Streamlining the MEP Design: Role of BIM Technology

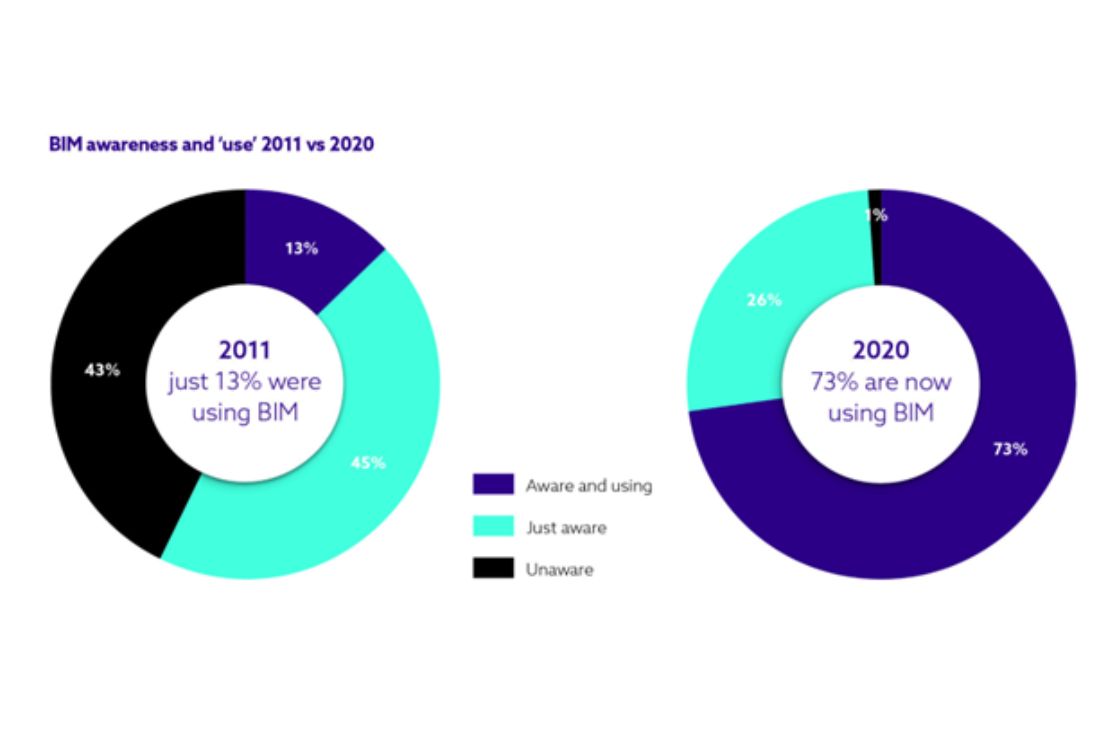

The AEC industry has been dependent on manual working methods and 2D workflow for several years. However, with the introduction of BIM modeling came a revolution that led to the 3D visualization of designs for better clarity. With platforms enabling MEP modeling, the results became even more efficient and promising.

Adoption of BIM in a project helps in enhancing productivity by approximately 60% while it cuts down the project cost by 21%. Overall, the design and construction process has become smoother and clash-free. But how is BIM helping in MEP designs and installations? Let’s learn.

Features BIM Technology Brings to the Table

BIM modeling is a technology that not only helps in designing but constructing, operating, and maintaining a project as well. The integrated approach helps in streamlining the work and establishes better communication among stakeholders.

As BIM offers error-free working, it helps in enhancing efficiency and improving the quality of design. The complexity involved in MEP designing and installation is made smoother as MEP modeling helps in forming better collaboration within the teams involved. Overall, from conceptualization to maintenance, each aspect of a design is catered to by BIM.

BIM Operations for MEP Design

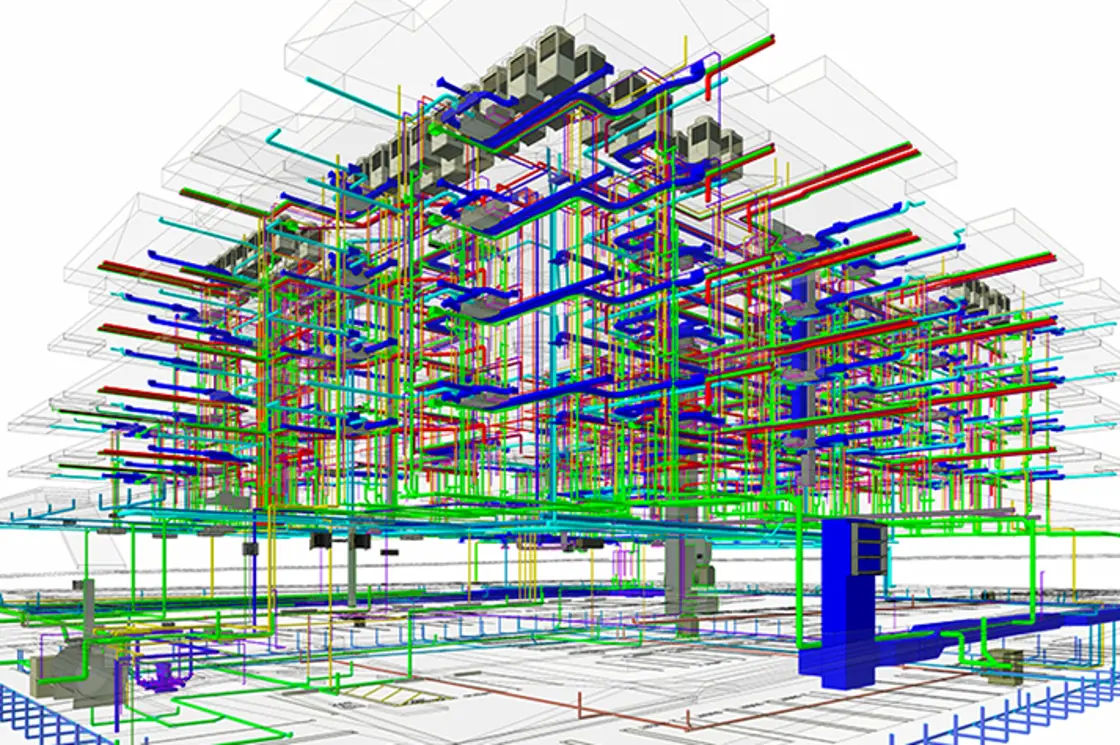

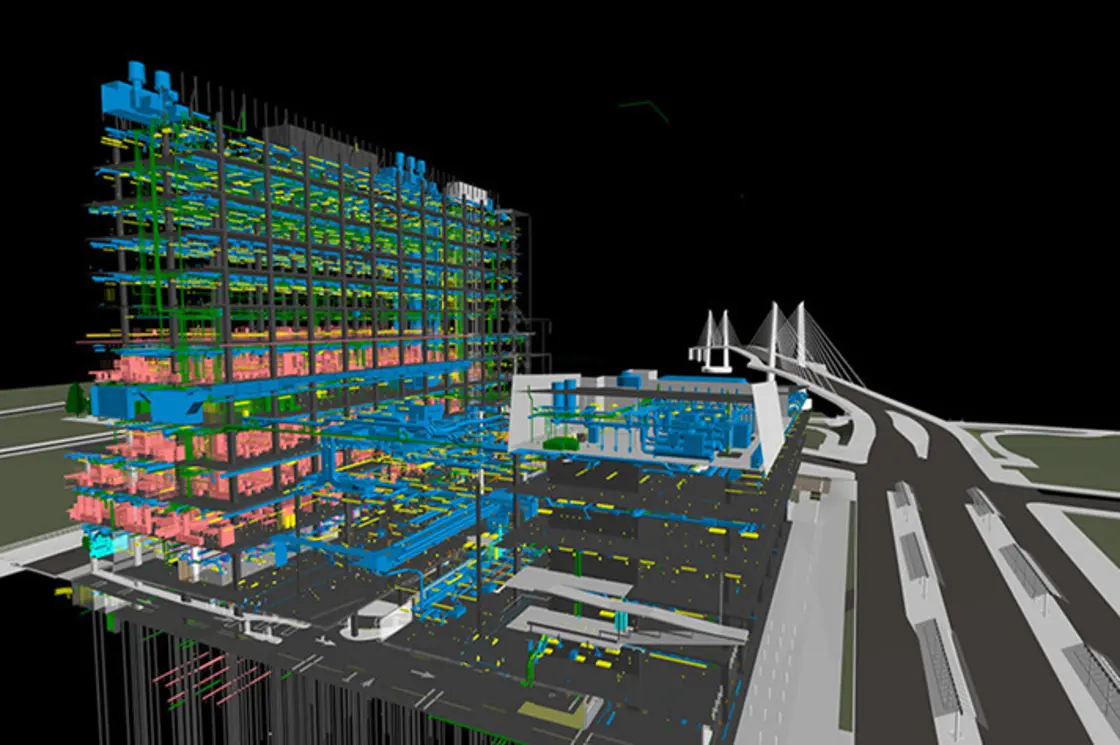

MEP modeling with the BIM platform helps in error-free designing and execution with the following operations:

1. Design Calculation

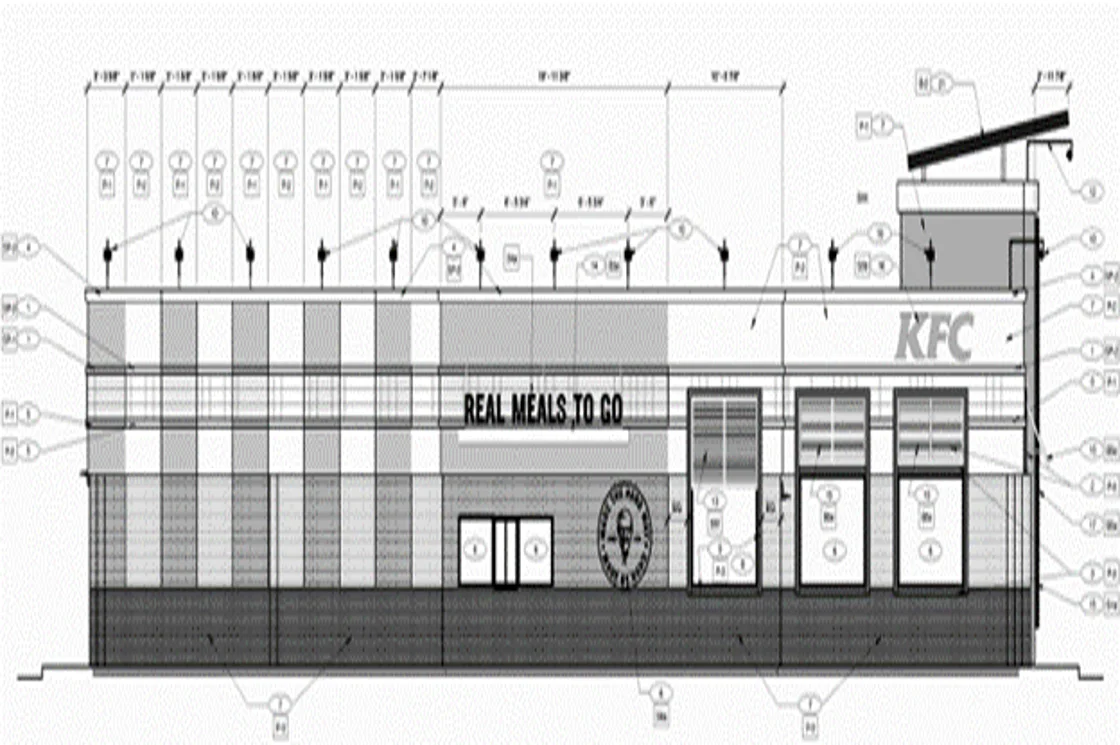

BIM modeling for MEP professionals helps in performing calculations on the go based on architectural elements like room size and orientation. Based on these parameters, power load, and heat load calculations are finalized.

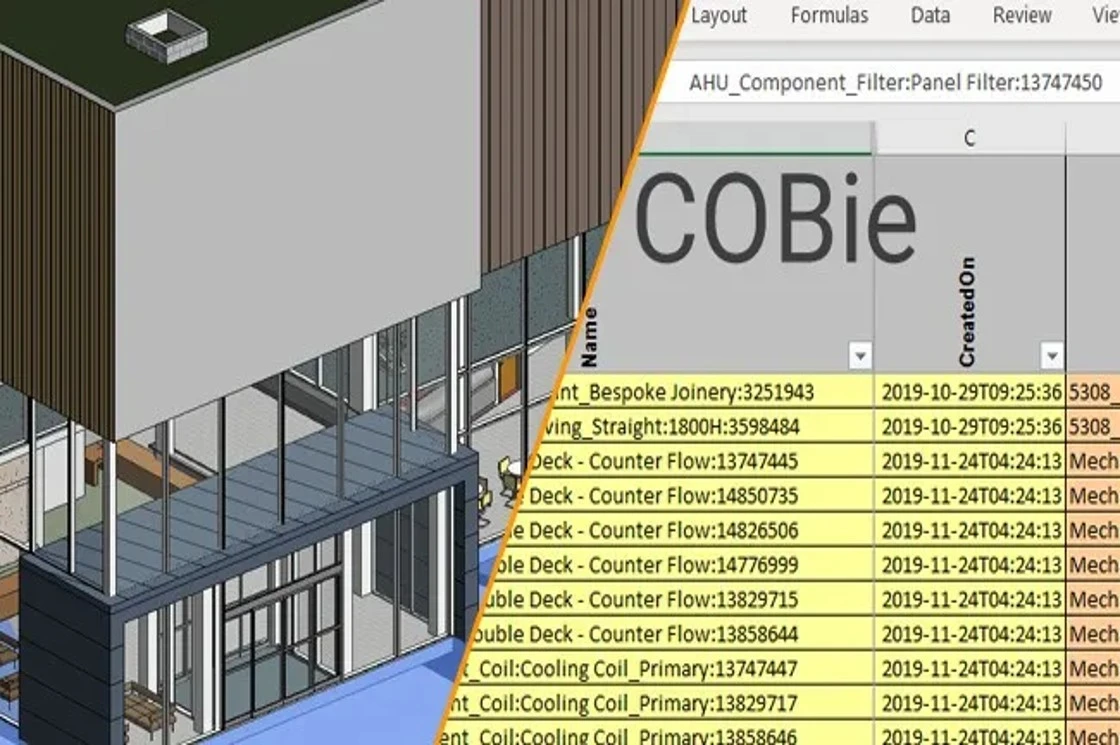

2. Equipment Selection and Cost Estimation

Once the design part is finalized followed by equipment selection, using BIM accurate equipment schedules can be prepared and extracted for estimating cost involved in MEP equipment purchase. Detailed equipment families added to the model helps to keep a check on cost if there is any change in equipment at a later stage .i.e. in case of changes in the architectural layout, the MEP engineer can cross-check the compliance of the selected equipment model and revise the equipment followed by cost estimation as per.

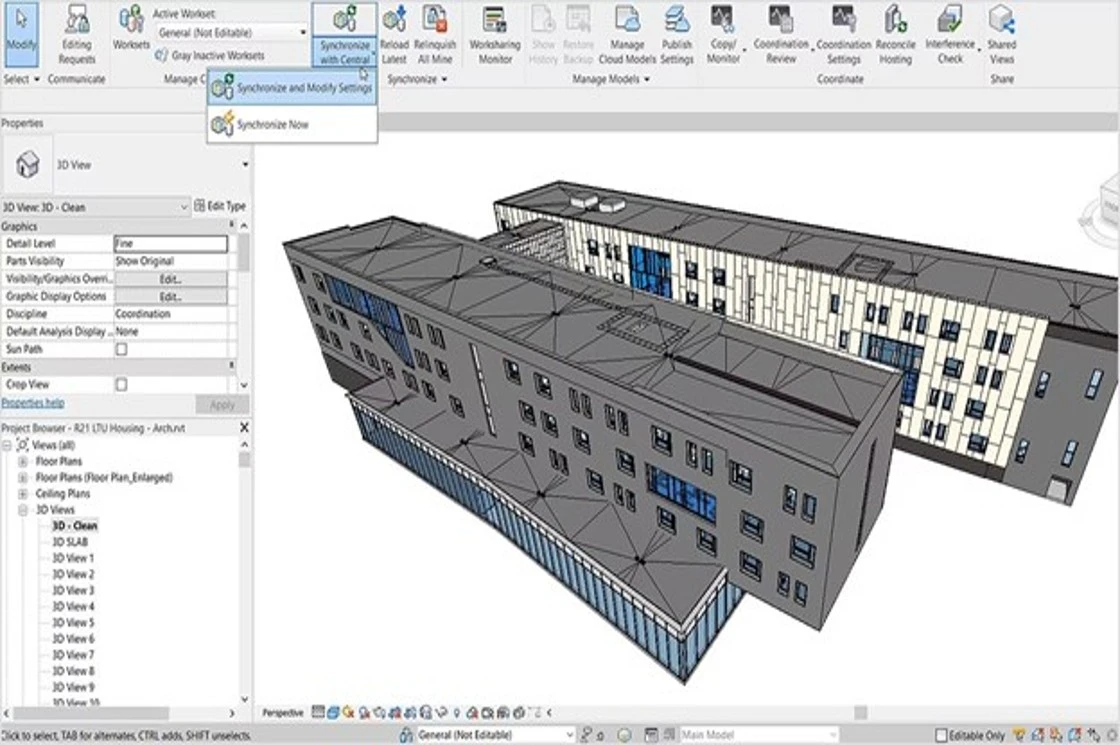

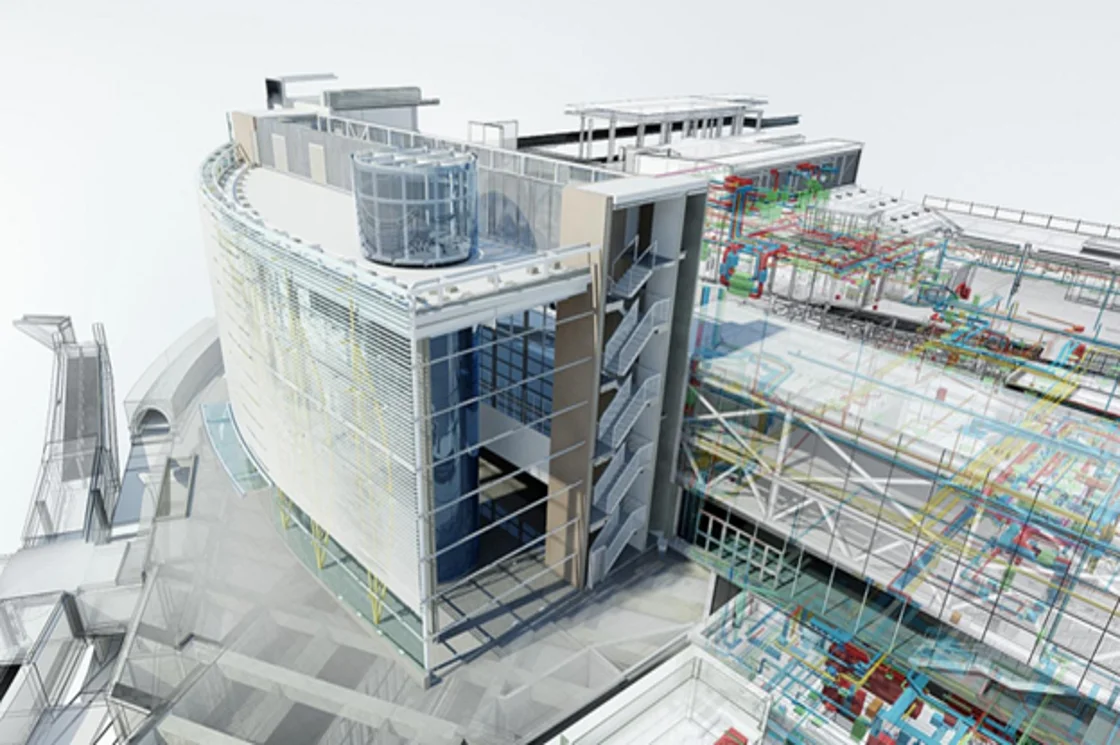

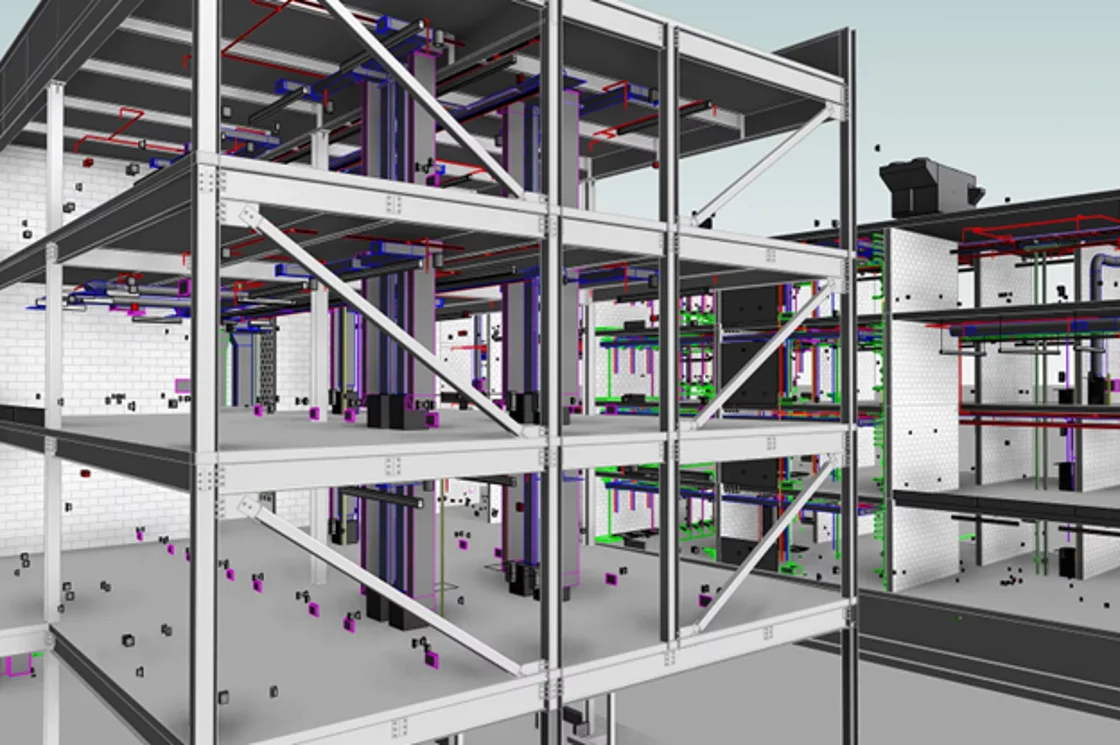

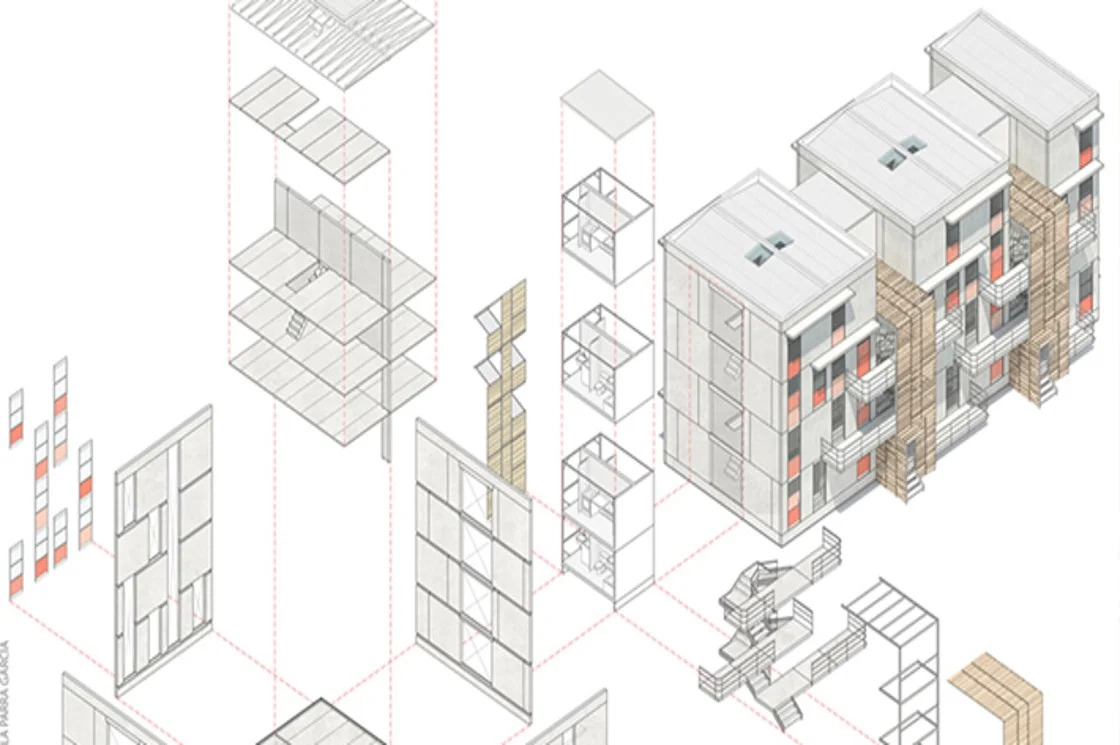

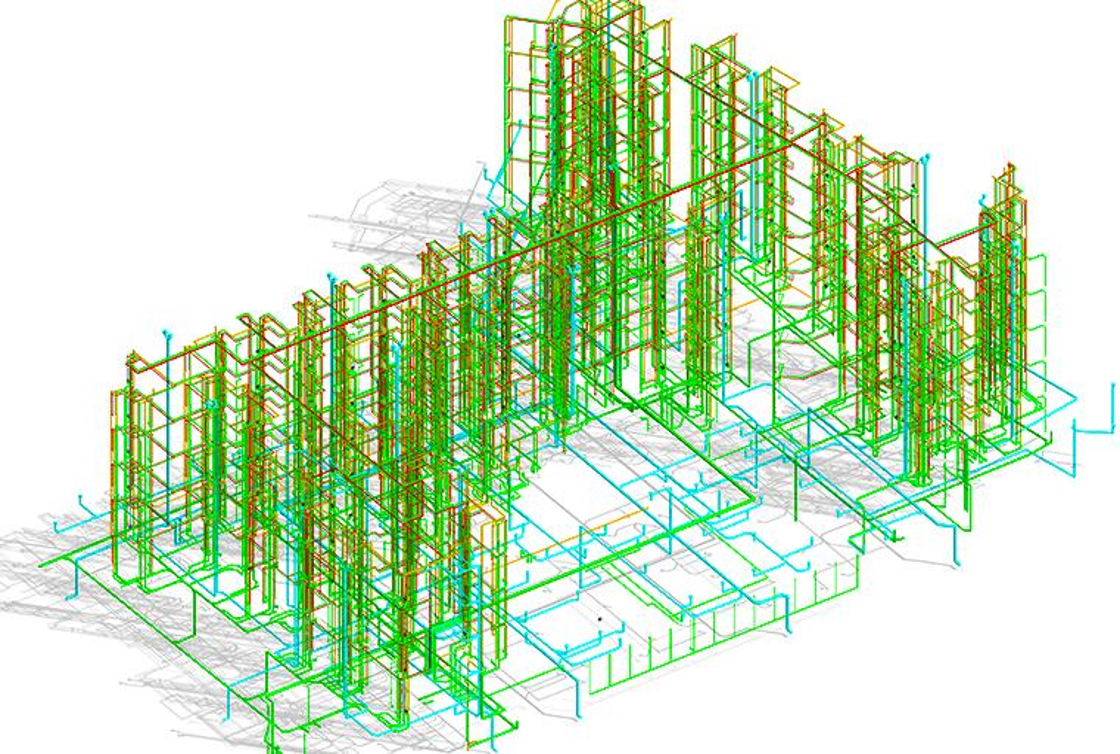

3. 3D Modeling and Coordination

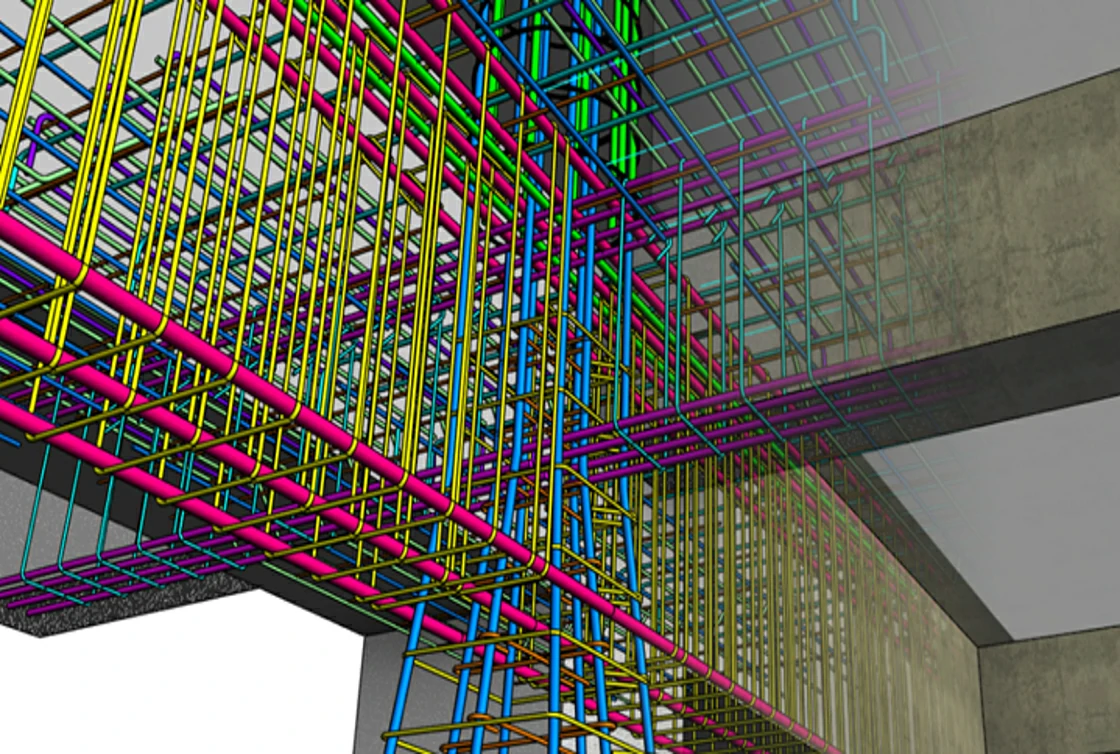

3D modeling and clash coordination are one of the major operations offered by BIM-compliant platforms. The visual representation makes it easier to analyze the design and customize it as per suitable services.

4. Cost Finalization and On-site Delivery

Once the model is checked and ready, the cost finalization can be conducted and on-site construction can begin. MEP modeling ensures error-free and quicker project delivery.

Top 9 Reasons to Adopt BIM for MEP Design

1. Accuracy

With better collaboration and rapid information exchange amongst different teams, the overall design promises accuracy.

2. Optimization

Iterations within the design at earlier stage of project development, helps in generating optimized design layout for each of the building discipline, be it architecture or MEP.

3. Better Visualization

Revit modeling lays the entire visual picture of the project on screen with all the design elements integrated with structure and building services that make it easier to analyze and visualize.

4. Communication

The transparency of working with MEP modeling ensures better communication amongst teams that minimizes the chances of clashes.

5. Estimation

The vital engineering calculations and cost estimations can be performed with a few steps in BIM modeling.

6. Risk Reduction

The chances of on-site hazards and risks are cut down as MEP modeling helps in composing clash-free layouts with the right equipment sizes.

7. Coordination

MEP modeling enables coordination that keeps the entire project in sync with all the teams.

8. Money-saver

Clash coordination and promised efficiency of design help in cutting down costs in a project.

9. Better Quality

As BIM modeling helps in design calculations, followed by accurate sizing leading to error-free layouts, better quality in projects can be expected.

MEP Modeling with BIM

The integration of MEP with BIM technology has helped to make the entire process smoother that results in high quality. It fills the communication gaps and presents the right infrastructure with accurate calculations. Partnering MEP with BIM workflows aids in the quick completion of projects without hindering quality.

AEODC has been a pioneer in incorporating MEP design know-how into BIM workflows delivering bespoke MEP BIM models that stand apart. Want to know more? Visit us at https://www.aeodc.com

Common Queries:

1. How is BIM helping the construction industry?

BIM modeling has proved to be an extremely efficient way of working for the construction industry as beforehand clash detection minimizes the risk of hazards on-site, and saves time and resources.

2. Are there different Revit Templates for Mechanical, Electrical, and Plumbing?

Revit modeling offers different templates for mechanical, electrical, and plumbing in a project. The template can be combined into one single file at the end.

3. Which BIM software can be used for MEP design?

Software like Revit, Navisworks, SolidWorks, AutoPIPE, etc can be used for MEP design.